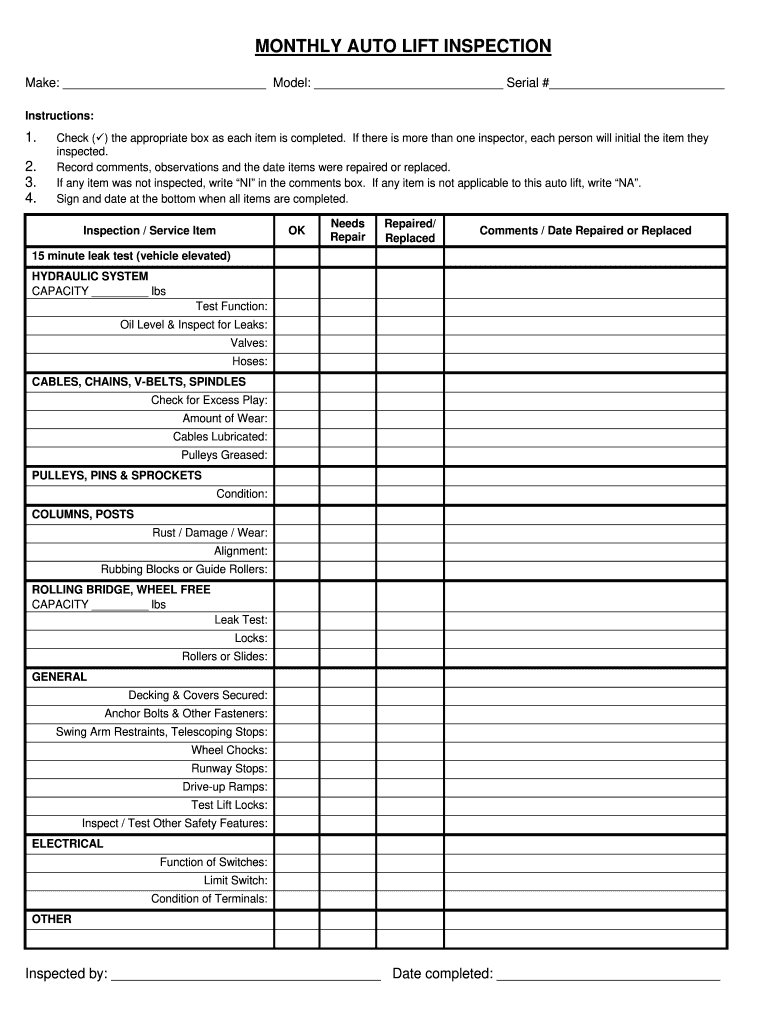

html Download FREE Forklift Inspection Checklist & Avoid Downtime! Download Your FREE Weekly Forklift Inspection Checklist Template NOW & Avoid Costly Downtime! Forklifts are essential pieces of equipment in warehouses, construction sites, and various other industries. Their efficient operation is crucial for productivity and profitability. However, without proper maintenance and regular inspections, these powerful machines can quickly become liabilities. This article will explain why a weekly forklift inspection checklist is vital, what should be included, and how to download a free, ready-to-use template to help you keep your forklifts running safely and efficiently. Why Regular Forklift Inspections Are Crucial Ignoring forklift maintenance can lead to significant problems. These include: Increased Downtime: Breakdowns halt operations, leading to lost productivity and missed deadlines. Safety Hazards: Faulty forklifts pose risks to operators and other employees, potentially resulting in serious injuries or fatalities. Higher Repair Costs: Addressing minor issues promptly prevents them from escalating into expensive repairs. Legal and Regulatory Compliance: Many jurisdictions mandate regular forklift inspections. Failure to comply can result in fines and legal repercussions. [Link to OSHA website regarding forklift regulations] Reduced Lifespan: Neglecting maintenance shortens the lifespan of your forklifts, leading to premature replacement costs. Regular inspections, especially using a reliable forklift inspection checklist, are the most effective way to mitigate these risks. They allow you to identify and address potential problems before they become major issues, ensuring a safe and productive work environment. What to Include in Your Weekly Forklift Inspection Checklist A comprehensive forklift inspection checklist covers a wide range of components and systems. Here’s a breakdown of key areas to examine: Pre-Operational Checks These inspections should be performed before each shift or at the start of the day. This checklist focuses on immediate safety and functionality. Fluid Levels: Check the engine oil, coolant, brake fluid, and hydraulic fluid levels. Low fluid levels can cause serious damage. Tires: Inspect tires for wear, damage, and proper inflation. Worn or damaged tires can compromise stability and control. Forks: Examine the forks for cracks, bends, and proper locking. Damaged forks are a significant safety hazard. Safety Equipment: Ensure the horn, lights (headlights, taillights, and warning lights), and backup alarm are functioning correctly. Steering: Check for smooth steering and proper responsiveness. Brakes: Test the service brakes and parking brake to ensure they function effectively. Seatbelt: Verify the seatbelt is in good working order and functioning correctly. Overhead Guard: Inspect the overhead guard for damage or obstructions. Operational Checks These checks are performed while the forklift is operating, allowing you to assess performance and identify any unusual behavior. Lifting and Tilting: Test the lifting and tilting mechanisms to ensure they operate smoothly and without any unusual noises. Load Handling: Check the load handling capabilities and ensure the forklift can safely lift and transport the intended loads. Controls: Verify that all controls (e.g., accelerator, brake, lift/tilt levers) respond correctly. Stability: Observe the forklift's stability, especially when maneuvering with a load. Benefits of Using a Standardized Checklist Using a standardized forklift inspection checklist offers several advantages: Consistency: Ensures all critical components are consistently inspected, regardless of the operator. Reduced Errors: Minimizes the chances of overlooking important items. Documentation: Provides a record of inspections, which is essential for compliance and accident investigations. Improved Safety: Proactively identifies potential hazards, preventing accidents and injuries. Increased Efficiency: Helps to identify and address minor issues before they escalate into major breakdowns, minimizing downtime. Download Your FREE Forklift Inspection Checklist Template To help you implement a robust forklift inspection program, we're providing a free, downloadable weekly forklift inspection checklist template. This template is designed to be user-friendly and comprehensive, covering all the essential inspection points. [Insert a hypothetical download link here, e.g., "Download the Free Checklist Now!"] By using this template, you can quickly and easily establish a regular inspection routine, helping you to maintain a safe and productive work environment. You can customize this template to suit your specific forklift models and operational needs. Consider adding fields for the forklift's serial number, the date of inspection, the operator's name, and a section for noting any required repairs or maintenance. Implementing Your Forklift Inspection Program Once you've downloaded your checklist, it's crucial to implement it effectively. Here are some best practices: Training: Provide thorough training to all forklift operators on how to use the checklist and identify potential problems. Regular Use: Ensure inspections are conducted consistently, ideally at the beginning of each shift. Documentation: Maintain a record of all inspections, including the date, time, operator, and any findings. Prompt Repairs: Address any identified issues immediately. Don't delay repairs. Review and Update: Regularly review and update your checklist to reflect any changes in equipment, regulations, or operational procedures. Consider using a digital inspection system [suggesting a link to relevant software] to streamline the process and ensure data accuracy. Conclusion Implementing a regular forklift inspection program is not just a good practice; it's a critical component of a safe and efficient workplace. By downloading and using our FREE weekly forklift inspection checklist template, you can proactively identify and address potential problems, minimizing downtime, reducing repair costs, and, most importantly, protecting the safety of your employees. Don't wait until a problem arises; take action today and ensure your forklifts are operating safely and effectively. Download your free checklist now and take the first step towards a safer and more productive workplace! [Repeat download link here, e.g., "Get Your FREE Forklift Checklist Now!"]

Download Your Free Weekly Forklift Inspection Checklist Template Now & Avoid Costly Downtime!

```html Download FREE Forklift Inspection Checklist & Avoid Downtime! Download Your FREE Weekly Forklift Inspection Checklist Template NOW & Avoid Costly Downtime! Forklifts are essential...